Steer mill operations towards shared goals

Valmet Mill-Wide Optimization

Unlock the full potential of your mill with Valmet Mill-Wide Optimization (MWO) - a revolutionary approach to enhancing overall profitability. With MWO, mill production teams are equipped to make well-informed decisions that boost present and future performance by aligning the decisions across different process areas towards shared goals. Operating in real-time, Valmet Mill-Wide Optimization takes into consideration the entire mill balance and considers both the current and future states of the mill, including process area interruptions and slowdowns.

Production maximization and stabilization

On-spec quality and production at minimum costs

Visibility of process stream quality, cost, and worth across the mill

Valmet as a partner towards autonomous mills

Next level optimization

Enabled by digitalization and data connectivity, and a long history of optimizing individual process areas, the pulp and paper industry is transitioning towards self-governing operations at the mill level.

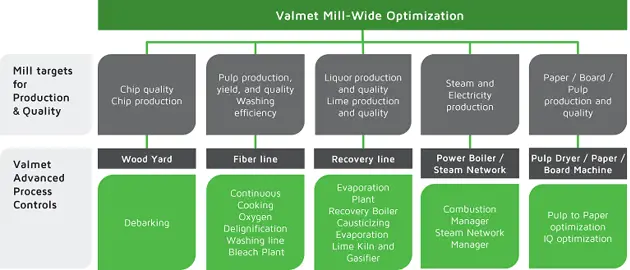

Valmet Mill-Wide Optimization models the behavior and relationships between unit operations so that mills can be optimized as a whole. As a result, suboptimization of individual processes that do not align with mill goals can be avoided.

MWO also provides the ability to balance environmental sustainability with production, quality, and cost.

Continuously push production towards mill limits

Mill-wide production planning

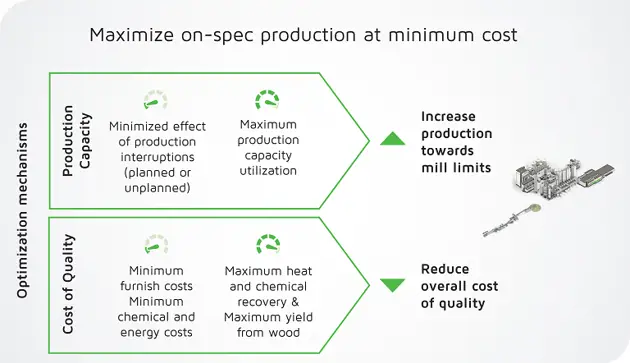

To keep up with the daily changes in mill production limits, the mill-wide production planning solution adapts its models in real-time to reflect the mill's current state. Valmet MWO then maximizes production subject to existing and projected limits, while stabilizing the process and balancing pulp and liquor inventories.

Valmet Mill-Wide Optimization is powered by state-of-the-art dynamic optimization software. The Valmet DNAe User Interface provides a future-looking view of pulp, paper, and liquor production rates and inventories, and the ability to account for both planned and unexpected production slowdowns and stops.

On-spec final quality met at minimum costs

Mill-wide quality planning

The production of pulp and paper at each stage can impact both its quality and the cost of producing that quality.

The mill-wide quality planning solution helps attain the desired final product quality while keeping costs low by monitoring and forecasting the quality and cost of the pulp throughout the process and adjusting the quality targets at each step from chip to finished product.

Valmet MWO serves as a coordination layer for individual Valmet Advanced Process Control (APC) applications which keep quality on target for their respective process areas. This coordinated effort helps to ensure that final quality remains on target while optimizing the use of resources across the mill.

Continuous collaboration and support

Maintain and exceed performance targets

Pulp and paper mill conditions and objectives are constantly changing. The pulp and paper industry is also transitioning to a younger workforce with new roles and responsibilities. Continuous collaboration between mill personnel and Valmet helps ensure these changing needs are addressed by maximizing the long-term effectiveness of Valmet MWO.

Valmet Performance Center experts provide remote interactive mill assistance, as well as proactive remote monitoring and analysis. In addition, Valmet's optimization and process experts periodically visit mills to resolve problems, review use cases, perform refresher training, adjust performance objectives, and provide consulting services. Together, these services establish a support structure, which guarantees long-term success through sustained effort and collaboration.

Let’s get started by reoptimizing the past

Valmet Mill-Wide Optimization Audit

Reveal your mill's true production potential and maximize your ROI with a Valmet Mill-Wide Optimization Audit. Our team of automation and process experts will conduct a comprehensive, in-person audit to identify your mill's operational bottlenecks and investment opportunities.

Valmet experts conduct interviews with your mill's operations staff and collect detailed process information. Historical data is analyzed to build production models for each process area. Using these models, we re-optimize the past mill operations to evaluate production increase potential.

By ranking production optimization bottlenecks, we'll identify the day-to-day limitations of your mill, and highlight use cases of mill-wide optimization. Our audit typically uncovers several investment opportunities, including new equipment, services, and automation.

Contact us to schedule your MWO audit

Don't let inefficiencies hold back your mill's potential. Let us help you uncover the investment opportunities that will improve your mill's performance and increase your bottom line.

Contact us

Downloads |

||

|---|---|---|

| Valmet Mill-Wide Optimization datasheet | ||