Automation for pulp makers

Future proof your mill: achieve production and sustainability goals

Did you know that most of the pulp produced around the world is measured or controlled by Valmet’s innovative automation solutions? Backed by our experienced team of process automation experts, Valmet is the most dedicated supplier for pulp makers and the only mill-wide OEM automation and pulp process equipment supplier in the world. Our complete offering maximizes what matters most to our customers, including the sustainability, safety and reliability of their pulp mill operations. It’s why more pulp mill operations around the world are choosing Valmet as their automation partner for pulp.

Automation for pulp processes

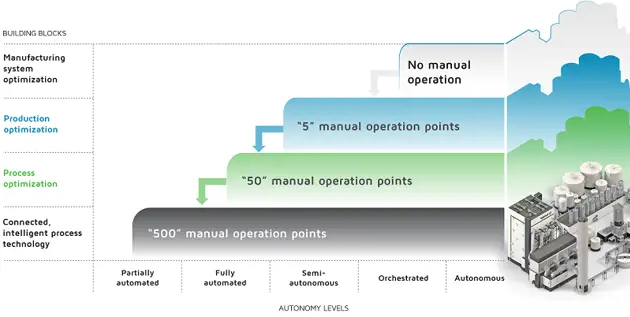

Enable the path towards autonomy

Autonomous and optimized operations are increasingly becoming the goal for pulp mills worldwide, offering enhanced safety and efficiency, cost reductions, minimized human errors, and lower environmental impacts.

Empowering people to perform at their best

Valmet’s pulp mill automation solution offers complete situational awareness, providing a structured, user role-based view to essential operational information. And because the data is readily accessible from any device, users can monitor and control the process regardless of their physical location. These mill-wide process controls enabled by reliable analyzers and measurements are essential elements of increased people performance, allowing operation teams to focus on the most meaningful process KPIs.

Valmet’s innovative Mill-Wide Optimization (MWO) gives mill production teams the data and details they need for accurate production and quality planning.

Reach your production, quality and environmental targets

On-target quality by controls throughout

Valmet offers pulp mill department specific quality measurements and controls from woodyard to baling. End-to-end quality is tracked mill-wide, with critical assets monitored by our asset performance monitoring solutions at every stage.

When quality and weight of every bale is optimized and tracked, you can trust that pulp quality leaving the mill is managed by the world’s leading pulp automation.

Automation for optimizing operational costs, sustainability and efficiency

With decades of experience working closely alongside pulp-makers, we can offer Advanced Process Controls for all pulp process areas, which are designed to minimize operation costs and ensuring maximum operational performance in each unique process area of the mill. Mills continually must do more with less, and our solutions for autonomous pulp mill operations enhanced by training simulators are helping to increase people performance.

Our customers are seeing the results in cost savings from reduced wood, chemicals and energy and an increase in pulp yield, steam and electricity generation, all while minimizing their mills’ environmental footprints.

With process-specific advanced automation and Valmet Mill-Wide Optimization, we maximize mill production efficiency in real-time by leveraging the utilization of process equipment while balancing pulp and liquor inventories and optimizing department specific quality targets. The result is increased pulp yield, energy and chemical efficiency and stable pulp quality with maximum runnability. And with intuitive tools offering available data around pulp, energy and chemicals in real-time, vital information is a glance away, allowing for faster and more accurate decision-making.

Our automation solutions for pulp processes and islands

Evolve throughout the lifecycle with a committed partner

Full service for better reliability at every step

Improving the reliability of pulp mill operations comes naturally to us at Valmet, as we help to ensure higher asset performance while minimizing unplanned downtimes. Our solutions enable you to make the right choices based on predictive diagnostics of automation and process equipment performance.

And with our team of Valmet service experts close by, support is always available throughout the lifecycle to help optimize your processes and ensure the highest levels of performance and availability.

Safer and cybersecurity-certified

Our pulp automation ensures safer and more efficient operations for pulp production by secure and user role-based location-independent access to data.

Safety integrated systems, process equipment specific safety applications and automated process analyzers all improve field operations. Our solutions are cybersecure throughout the line, from field equipment to distributed control systems (DCS) all the way up to process and production optimization.

Are you interested in specifications, prices and expert services?

Our experts are here for you and ready to discuss your challenges. Just answer a few questions and we will contact you shortly.

Contact usLatest news

- Oct 21, 2025Valmet to supply a BioTrac system with automation for OutNature's agro-residue straw-pulp project in Germany

- Oct 15, 2025Valmet delivers a new energy-efficient evaporation line to Altri in Portugal for mill conversion to dissolving pulp production

- Jul 9, 2025Valmet launches Pulp Filtrate Extractor for ensuring the highest availability and accuracy for pH measurement in pulp making

- Jul 8, 2025Valmet to deliver key pulp mill technology to Shandong Sun Paper’s Yandian pulp mill in China

- Jun 18, 2025Valmet and SAMK strengthen cooperation to foster future expertise

- Apr 3, 2025Valmet to deliver a new bleach plant, and an evaporation and wash plant rebuild to Grasim Industries Limited in India

- Nov 21, 2024Valmet to deliver a modern lime kiln to Kuantum Papers Limited in India

- Nov 13, 2024Valmet to deliver a cooking plant pre-evaporator upgrade for Mercer Rosenthal in Germany

- Oct 17, 2024Valmet to deliver an automatic dewiring line to Södra Cell Värö in Sweden

- Sep 20, 2024Valmet to supply a new BCTMP line and an evaporator line to JK Paper Limited in India