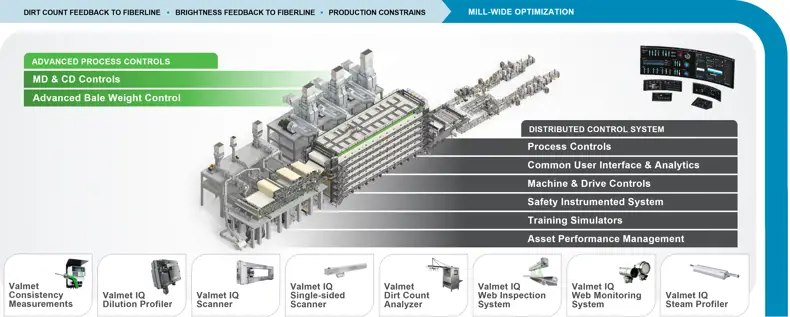

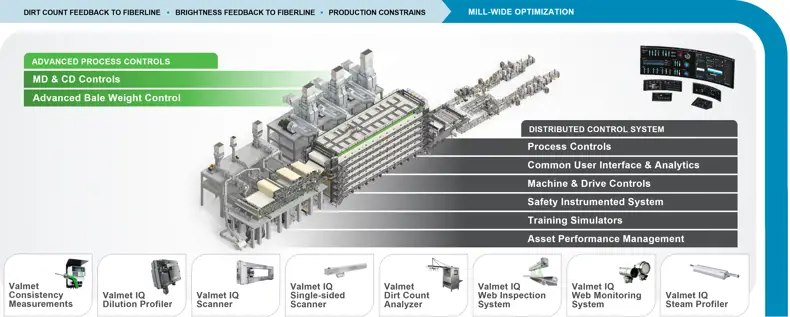

Pulp drying and baling automation

Essentials for autonomous operations

Our automation solutions for pulp drying and baling ensure maximum production capacity and energy efficiency while maintaining precise, tracked pulp quality. Our advanced condition and performance monitoring solutions cover all process equipment and control loops. As we move towards autonomous operations, our fully automated process quality control solutions enhance safety and situational awareness by managing all key process variables.

On this image

-

1 Mill-Wide Optimization

-

2 Advanced process controls (APC) for Pulp

-

3 Distributed control systems (DCS)

-

4 Consistency measurements

-

5 Valmet IQ Dilution Profiler

-

6 High-speed scanners for precise quality control

-

7 High-speed single-side scanning

-

8 Dirt Count Analyzer

-

9 Advanced quality control for pulp drying

-

10 IQ Web Monitoring System

-

11 Valmet IQ Steam Profiler

Mill-Wide Optimization

Valmet Mill-Wide Optimization (MWO) helps pulp and paper mills to increase their overall profitability and steer their operations towards shared goals.

Advanced process controls (APC) for Pulp

Maximizing process performance is a critical success factor as it directly increases profitability.

Distributed control systems (DCS)

Valmet DNA and Valmet DNAe are safe, future-proof distributed control systems built on your industry's leading process know-how. They empower your people to perform at their best, utilizing a unified user interface and sharing advanced data analytics from Valmet DNAe. With lifetime systems compatibility, step-by-step upgrades, and seamless migration from other DCS and PLC systems, you can unlock the full potential of your 24/7 operations for decades to come.

Consistency measurements

Valmet's development of consistency measurements is based on over 40 years of experience

Valmet IQ Dilution Profiler

Valmet IQ Dilution Profiler has been specially designed for achieving the best possible weight profile that a headbox can produce.

High-speed scanners for precise quality control

At the heart of the Valmet IQ quality control systems are Valmet IQ Scanners. Featuring unique adaptive scanning capabilities, they can be used with a wide of range high-quality online measurements for precise quality control.

High-speed single-side scanning

Featuring intelligent adaptive scanning, the Valmet IQ Single-Sided Scanner is engineered for quality control in challenging locations with restricted machine space.

Dirt Count Analyzer

The Valmet Dirt Count Analyzer (Valmet DCD) is an analyzer used for measurement of dirt count and brightness from pulp sheets at the baling line.

Advanced quality control for pulp drying

The Valmet IQ Web Inspection System for dirt count uses unique high-power lighting and intelligent camera technology to detect dirt and shive defects that used to go unnoticed. ISO 5350-2 standard-based customizable classification and automated online analysis help you identify and resolve critical defects and ensure continuous online quality control.

IQ Web Monitoring System

The newly enhanced Valmet IQ Web Monitoring System (Valmet IQ WMS) delivers unmatched performance for today’s demanding production environments. Designed for advanced process analysis, it enables operators to quickly identify and trace defect origins as they occur. With industry-leading illumination, sharper visuals and the most compact design available, it helps maximize product quality and efficiency across the pulp, paper, tissue, and paper & board converting industries.

Valmet IQ Steam Profiler

Valmet IQ Steam Profiler is the highest efficiency steam profiler family to increase production capacity, decrease energy consumption and improve moisture profile.

See all automation solutions for pulp processes and islands

Are you interested in specifications, prices and expert services?

Our experts are here for you and ready to discuss your challenges. Just answer a few questions and we will contact you shortly.

Contact us