Revolutionary technology for energy efficient curl control

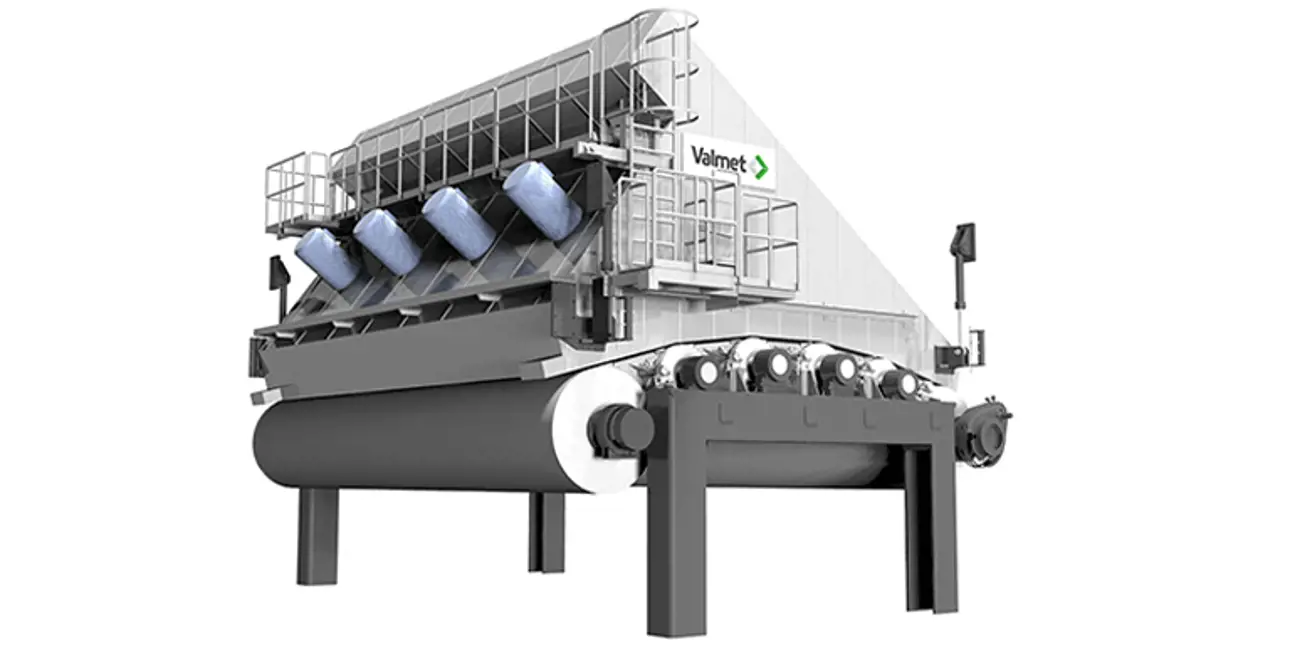

OptiDry Curl impingement dryer

OptiDry Curl, the new solution for curl control, is based on the impingement drying technology. Traditionally dryer groups with a double-felted configuration have been used for controlling the paper curl by adjusting different top/bottom dryer temperatures and affecting in this way drying on the two sides of the paper. Another traditionally used method is moisturizing (with water or steam), which also influences the curl of paper but at the same time increases paper moisture again.

Excellent curl control

Excellent runnability

Energy efficiency

In the new energy efficient method with OptiDry Curl, the other side (than dried by cylinder drying) of the web is dried last in which case stresses created in the paper are eliminated by relaxation as the dewatering direction changes. The power of impingement drying curl control is high and it even enables to change the direction of curl towards bottom side.

Curl control by OptiDry Curl is suitable both paper and board grades. No extra cylinders are required, which means a shorter machine hall and energy savings.

Excellent curl control

- curl control by drying not moisturizing

- easy to adjust curl

Excellent runnability

- supported web run

- easy tail threading

Energy efficiency

- no re-drying due to no moisturizing

- efficient heat recovery

Want to talk to our drying experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsInterested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsHow do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookPlanning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreExplore our latest board and paper press releases

- Nov 26, 2025Valmet supports Wuzhou Special Paper’s transition to recycled board grades with a complete paper machine conversion rebuild

- Nov 5, 2025Valmet to start change negotiations regarding temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Sep 16, 2025Valmet strengthens customer value by delivering a high-end sack and kraft paper machine for Guangxi Jianhui Paper in China

- Aug 21, 2025Valmet to supply two papermaking lines to a customer in China

- Aug 18, 2025Successful start-up of Sappi North America’s rebuilt board machine PM 2

- Aug 13, 2025Valmet launches next-generation Valmet Conical Refiner Conflo L model, designed for higher capacity and efficiency

- Aug 7, 2025Successful start-up at Liansheng Pulp & Paper’s coated board making line PM 2

- Jun 13, 2025Dr. Jin-Doo Kim awarded with a Medal for Extraordinary Achievement for decades-long work for promoting board and paper technologies

- May 26, 2025Valmet to supply a fifth Advantage tissue production line to Lila Group in Turkey

- May 21, 2025Valmet to supply a major paper machine rebuild to Sylvamo in North America