Supporting digitalization in hazardous environments with wireless valve communication

Advances in digital communication technologies are changing how field devices are integrated, maintained, and monitored across process industries. As protocols evolve and connectivity expectations grow, valve automation must also adapt. At Valmet, product development is closely aligned with real-world operational needs and industry standards.

To understand how these trends shape product strategy and support safer, more efficient plant operations, we spoke with Stonel product manager, Bruce Domino. This FAQ highlights key insights from that discussion, focusing on the development and role of the Stonel Wireless Link app in modern process environments.

Stonel™ Wireless Link App – Frequently Asked Questions

1. Why was the Stonel Wireless Link app developed, and when was it first released?

The app was developed to improve setup efficiency and reduce safety risks in process automation environments. By enabling wireless access to valve communication devices, it limits the need for direct physical access, particularly in hazardous or hard-to-reach areas. The Stonel Wireless Link app was first introduced for iOS in 2015.

2. What communication technologies does the app support, and how does IO-Link help improve visibility?

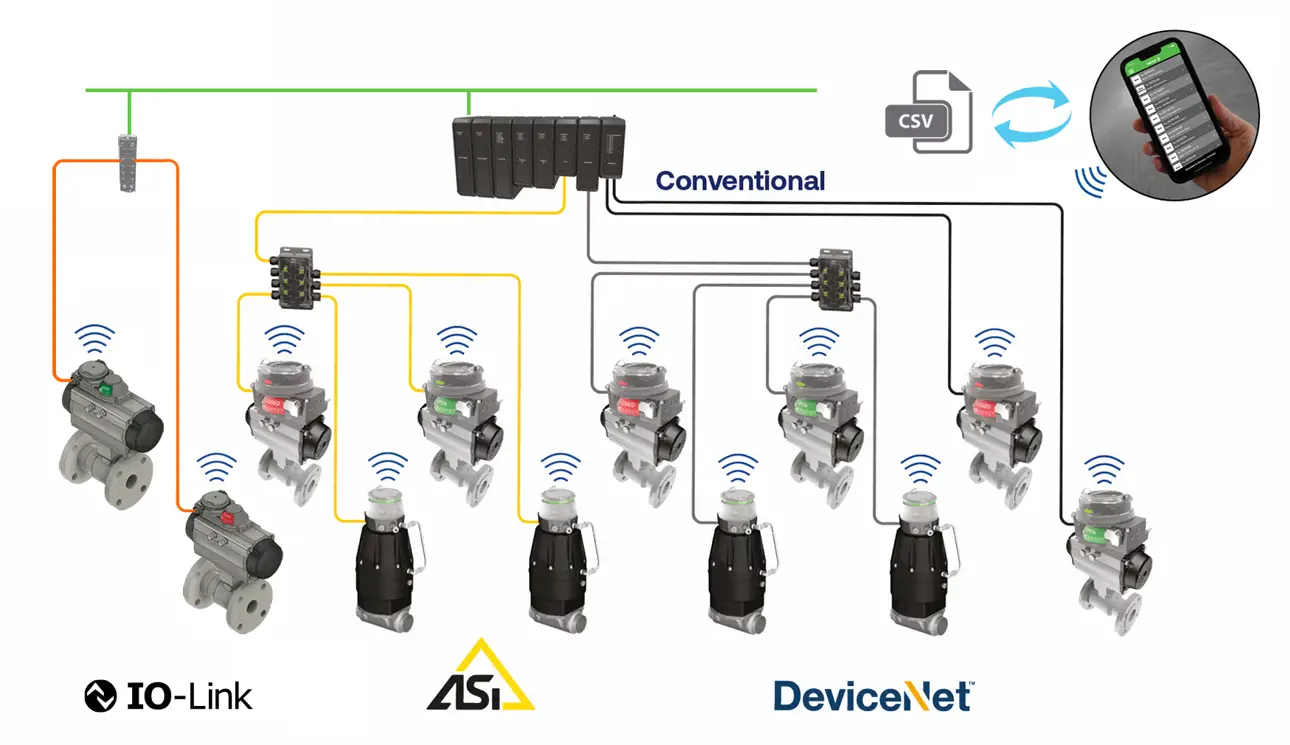

The app uses Bluetooth® technology for local wireless access and supports AS-Interface and DeviceNet protocols as well as conventional I/O and IO-Link applications. IO-Link allows direct communication between field devices and control systems. This provides access to real-time diagnostic data, simplifies device replacement, and supports condition-based maintenance. It also helps standardize connectivity in digitalized process environments.

3. Which Stonel platforms include wireless functionality, and what are their key applications?

Wireless capabilities are available on the following Stonel platforms:

- Axiom™ and Eclipse™: Built for rotary on/off valve applications. These platforms are commonly used in chemical processing, oil and gas, food and beverage, water treatment, and other industries that require reliable position feedback and control for standard on/off service.

- Prism™: Designed for linear valve applications. Its compact and modular construction makes it well suited for space-limited installations, including pharmaceutical and specialty chemical facilities where precision and access control are important.

All platforms include integrated Bluetooth® connectivity for use with the app.

4. Which industries benefit most from the Stonel Wireless Link app?

The app supports safer, more efficient operations in industries where reliability and process continuity are essential. This includes:

- Chemical processing

- Oil and gas

- Water and wastewater treatment

- Food and beverage

- Pharmaceuticals

In these environments, wireless access helps reduce manual intervention, improves visibility into device status, and supports faster commissioning and diagnostics. As part of Valmet’s automation offering, the app contributes to improved plant reliability and safer working conditions, especially in confined or hazardous areas.

5. Which mobile devices are compatible with the app, and how does it support future automation?

The app runs on both iOS and Android platforms and is compatible with widely used industrial mobile devices, including iPads, Android tablets, and Google Pixel smartphones.

By enabling remote access, the app reduces the need for direct equipment handling. This helps minimize exposure to hazardous areas and supports safer work practices.

Looking ahead, Valmet is supporting future automation by advancing diagnostics to be supported in its Wireless Link and FieldLink network portfolio such as ASi-5 and IO-Link. The focus is on improved connectivity, real-time diagnostics, and remote asset management. These developments support more connected plants and align with Valmet’s broader strategy for intelligent process automation and long-term reliability.