Strategies for more reliable slaking and causticizing

Webinar Date: May 21st, 1 p.m. EDT, 45 minutes + Q&A

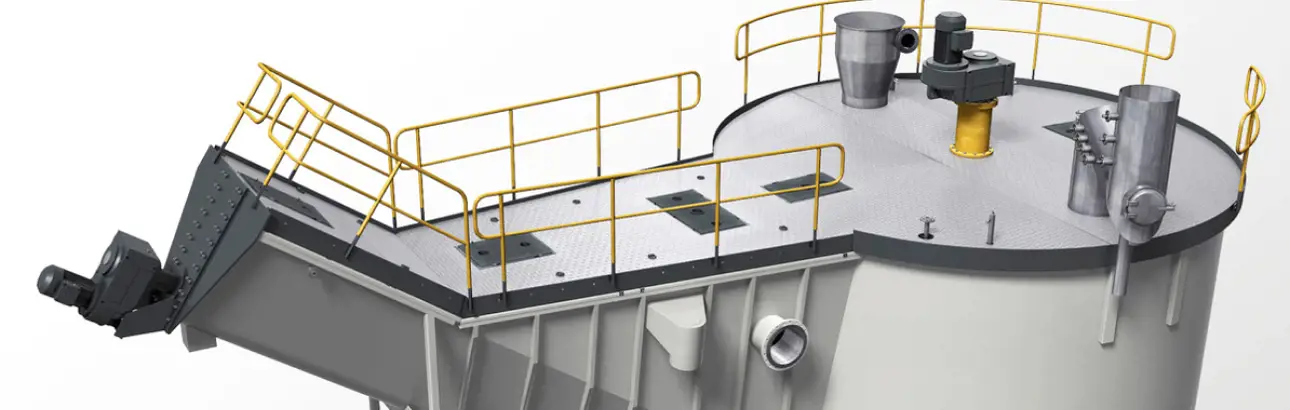

Slaking and causticizing are critical components of white liquor production, forming the backbone of an efficient and reliable chemical recovery cycle. Whether you're new to the recaust area or looking to stay updated on the latest technologies, this webinar will offer practical insights into system configurations, operational best practices, and innovations that can enhance process control and efficiency.

Join us for a comprehensive look at today’s slaking and causticizing systems, where we’ll explore equipment differences, recent technology developments, and proven ways to optimize your mill’s performance.

In this webinar, you will learn about:

- The purpose and role of slaking and causticizing in white liquor production

- Key differences between slaker and causticizing equipment types

- Advantages of new innovations in recaust technology

- How Online Slaker Control and Advanced Process Controls (APC) can improve efficiency and stability

Can't make the live session? Don't worry, once you register we will send you a full high quality recording of the webinar that you can review at any time.

We also offer a Certificate of Attendance for this webinar, which serves as a great way to showcase your professional development—perfect for sharing internally and externally to display on platforms such as LinkedIn to highlight your commitment to continuous learning. To receive a Certificate, you must attend up until the Q&A portion.

[NOTE: This event will be in the English language. This is only offered to process and energy industry facility owners, pulp, paper, board and tissue producers, process and energy industry consultants and university faculty and students. Use your company or university domain email address when registering. Products and services mentioned in this presentation may not be available in all regions.]

VALMET PRESENTER

|

Matthew Sparks Matthew began his career in the Pulp and Paper industry in 2020 after earning his degree from Mississippi State University. He quickly specialized in recaust operations, leading numerous improvement and optimization projects while gaining hands-on experience troubleshooting across mill departments. Matthew’s deep knowledge of white liquor plant operations was honed through roles at PCA Counce and IP Rome, with a focus on slaking and causticizing systems from the start. |