Bleached Stock Screening

Valmet offers several screening options and screen sizes before the pulp drying line; centrifugal separation with cleaners, machine screening and pressurized medium consistency screening with Delta screens in combination with a cleaner plant. All alternatives separate impurities, even with contamination of the approach system. Each system has its own advantages. The choice is driven by each application demand. Valmet has the widest range of screens, wide process knowledge and local service available world-wide.

Increases protection of wires, felts and headbox

Maximizes runnability and pulp web quality

Minimizes web breaks and machine direction basis weight variations

Energy efficient technology

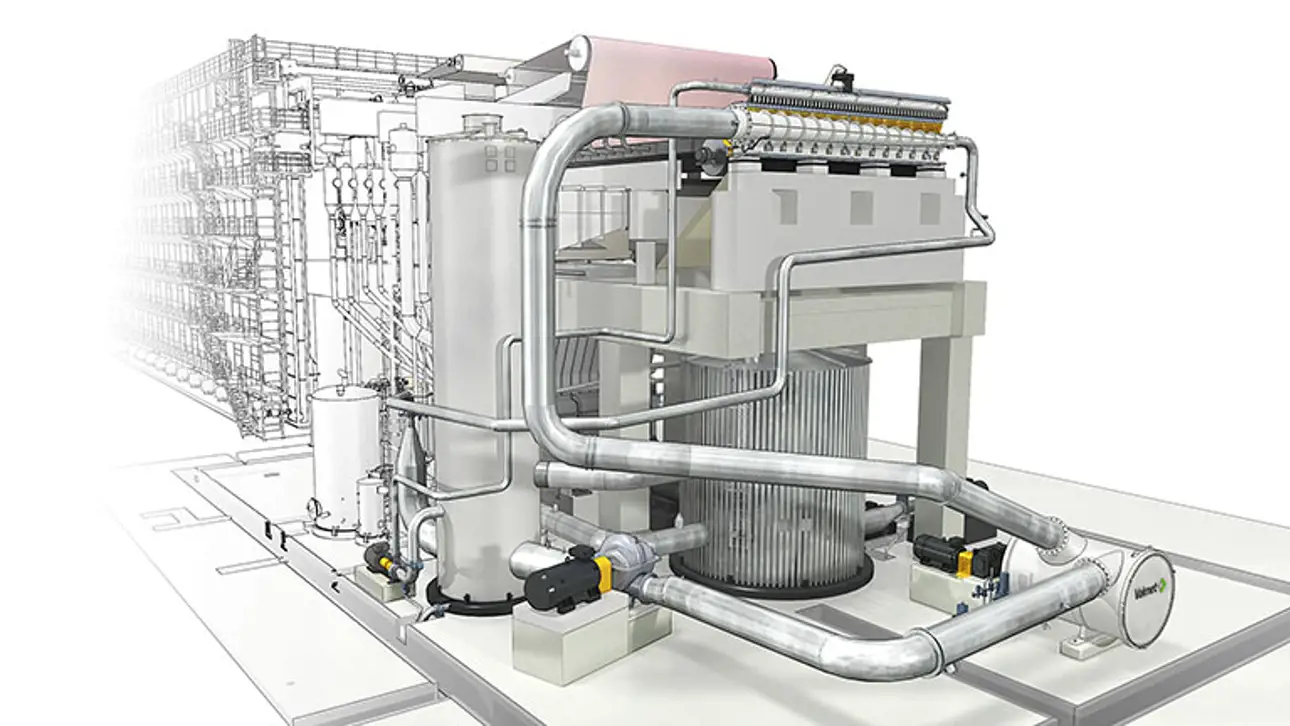

Valmet Twister Hydrocyclone

An optimal solution for high-consistency, high-demand hydrocyclone applications. Operating at up to 2% consistency, this two-stage hydrocyclone features three forward hydrocyclones in one, single unit. Valmet Twister Hydrocyclone features Mid-cone Dilution Technology and delivers energy savings with lower applied energy and lower reject rates than conventional Hydrocyclones. Read more about low consistency hydrocyclones

Low consistency cleaner plant for dissolving, fluff and other special pulp grades

A high-performance hydrocyclone designed for cleaning of bleached and semi-bleached kraft pulp, dissolving pulp or removal of mini-shives. It is also commonly used in waste paper deinking systems. Valmet Hydrocyclone TRP 90 is flexible, interoperable with Valmet Hydrocyclone Cleanpac 270 systems and can operate on Forward, Reverse, Thickening or Fractionation applications. Read more about the Valmet Hydrocyclone TRP 90

Pressurized machine screening

The OptiScreen technology’s screening efficiency is based on the design features of the outflow-type screen and the interaction of the patented rotor and foil. Pulsations are minimized by the foil shape and the screen body’s profiled electropolished surfaces. Valmet’s machine screening features a robust outflow design, sturdy rotor and foil support, and durable screen baskets.

Available in vertical and horizontal designs, the machine screens can be operated with both slotted and hole screen baskets. Read more about machine screening

Pressurized medium consistency screening

Valmet Fine Screen Delta is a fine screening system. It is designed for pulp consistencies up to 5% and achieves excellent screening results. Valmet Fine Screen Delta features the Nimega screen basket, delivers high efficiency shive removal and fulfills all capacity requirements. Read more about fine screens

Our expertise is at your service

Do you want to know what solution that would be best for your application or do you have questions regarding how to improve your existing screening room? Contact our experts today!

Contact us