Field services for mechanical pulping

Maintenance, repairs, analysis, and adjustments necessary to ensure reliable operations

Do you need defibrator, refiner equipment maintenance or support for mechanical pulping equipment or process performance development? We offer all types of on-site service such as audits, inspections, replacements, tuning with high level standards for safety and work quality.

Identify limitations & areas of improvement

Access to extensive network of expertise

Onsite & remote troubleshooting and maintenance

Where is your system today, and where can it be in the future?

Valmet Mechanical Pulping Process Audit is a tool that allows you to identify areas of improvement in your production line.

Valmet has the experience and resources to thoroughly evaluate the performance of your system. Moreover, Valmet can advise on the best way of investing in the Mechanical Pulping system to address limitations, optimize performance and maximize the return on investment.

Questions about equipment maintenance or support for equipment or process performance development?

Whether it’s a single process survey, equipment maintenance, shutdown management or full maintenance, don’t hesitate to contact your closest Valmet Service Center for guidance.

Contact us

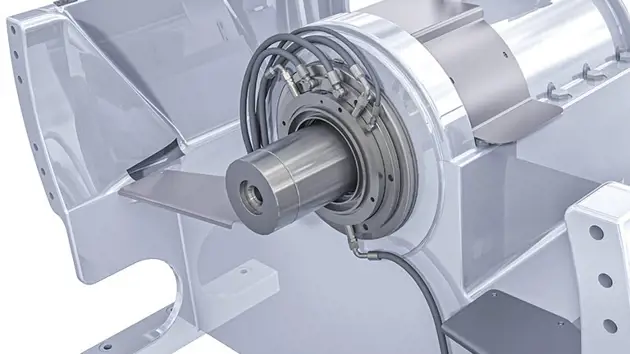

Improve the performance of the defibrator/refiner with Valmet Inspections

The service lifetime of a Defibrator/Refiner can be doubled by taking advantage of Valmet’s expertise of maintenance, repair, analysis and adjustments that are deemed necessary to ensure it is in reliable condition. Let us help you to reach these targets:

- Increased availability

- Performance improvements

- Recommendations of upgrade options

- Recommendations of spare parts

Find out more Valmet Inspections for defibrators/refiners.

Extend the lifetime of the defibrator/refiner - Valmet Drop-In Unit Replacement

Using Valmet’s experts when replacing a Defibrator/ Refiner drop-in unit assists in uncovering any considerable deviations that may affect its performance. Let us help you to reach these targets:

- Increased Availability

- Guarantee

Find out more about Valmet Drop-In Unit Replacement.

Extend the lifetime of the mechanical seals

Extend the lifetime of the mechanical seal by using Valmet’s expert knowledge of the maintenance, repair, analysis and adjustments that are deemed necessary to ensure it is in reliable condition. Let us help you to reach these targets:

- Increased Availability

- Process improvements

- Requirement of spare parts optimized

- Valmet’s expert knowledge secures correct installation

Read more about Valmet Mechanical Seal Replacement.

A process and mechanical inspection to increase productivity - Valmet TwinRoll Press Inspection

Valmet TwinRoll Press Inspection involves a process and mechanical inspection of a TwinRoll Press. When the audit is completed, the customer receives a detailed report containing recommendations for mechanical and process changes, spare part inventory as well as machine documentation. Let us help you to reach these targets:

- Fewer unplanned stops

- Increased accessibility

- Better pulp quality

- Higher productivity

- Proper machine documentation

- Right spare parts in stock - Less capital tied-up

Read more about Valmet TwinRoll Press Inspection.

Download Field Services Mechanical Pulping Handbook

Do you need equipment maintenance or support for equipment or process performance development? This handbook provides guidance on best practices to maintain your operation in good condition. It includes service interval recommendations to help prevent unexpected failures at your mechanical pulp mill.

Download

Download Field Services Chemical Pulping Handbook

Do you need equipment maintenance or support for equipment or process performance development? This handbook gives you guidance in best practices for keeping your operation in good condition at your chemical pulp mill.

Downloadkeyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}