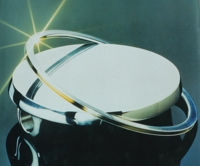

Put quality first with the new Valmet THRU-AIR® Bonder

With the introduction of the all new Valmet THRU-AIR Bonder nonwoven web producers now have an opportunity to invest in cost competitive equipment without compromising production quality.

Insights ● Article