Pivot Solution

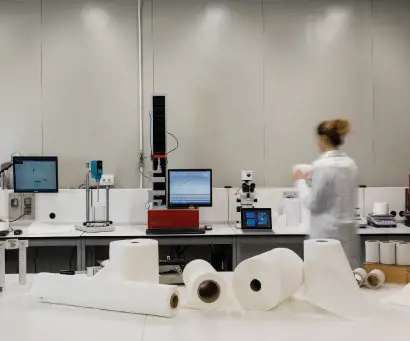

Pilot trials and laboratories for tissue converting

Pivot Solution combines long-standing expertise in tissue converting with deep knowledge of embossing technologies and advanced data collection capabilities. Whether you're looking to improve existing product quality or test new innovative ideas, Pivot Solution helps identify the ideal combination of paper, technology, and product features.

Develop new or improve existing products in a real production conditions

Testing new converting technology

Testing and validation of new embossing designs

Our services

Embossing development

Thanks to Engraving Solutions and Roll-Tec, we are the only tissue machinery manufacturer capable of offering all engraving technologies: mechanical, chemical, mixed and tool-based and direct laser engraving for non-metal surfaces and small-sized rolls or limited-size sleeves. We produce rolls for single or double Rubber-to-Steel embossers, DESL or nested, Point-to-Point, Deco-Embossing, steel to steel, match to steel, Fusion or other advanced techniques. We offer our customers complete solutions from the study of the embossing pattern to the production of trial samples and the supply of engraved rolls in order to launch new products, improve existing ones, venture into new markets and capitalize on new business opportunities.

Discover more about Engraving Solutions and Roll-Tec

Engraving Solutions website Roll-Tec webiste

Pilot trials - Run tests under realistic operating conditions

We offer a wide range of pilot lines in order to produce prototypes for evaluation purposes as well as simulate and test product performance at real operating conditions with the different winding technologies available on the market (3 or 4 rolls). Also, we can produce product samples to perform panel and market tests with dedicated production slots. Our prototyping capabilities are available worldwide for all our technologies, roll and fold products, including the most innovative ones like Solid and Solid+ rolls.

High speed pilot line

Location: Lucca, Italy

Line specifications

- Machine speed: up to 700 m/min, up to 45 log/min

- Paper width: up to 600 mm

- Max roll diameter: 1,800mm

- Finish product diam.: up to 200mm

- Multifunctional embosser

- Rubber-to-steel, single or double nip

- Single or double laminated DESL/SPOT (nested)

- Single or double laminated P/P (point-to-point)

- Matched steel, single nip

- Calender (rubber-to-steel)

- Double rubber to steel embosser

- Possibility to set up any type of embossing pattern available

- Configuration and components can be customized based on customer requirements

Latest technologies available

- Constellation 4-roll rewinder

- Active Punzoncini

- Self-Adjusting Machines devices

- Aquabond ply-bonding technology

- Leonardo lotioner

- Warm-up Contactless Next process for embossing

Low speed pilot line

Location: Lucca, Italy

Line specifications

- Machine speed: up to 40 m/min

- Reels: width up to 320 mm - diameter up to 500 mm

- N° 3 unwinders

- N°3 R/S station pre-embosser

- 1st Multifiunctional embosser - DESL, DERL, Point to Point – single or double lamination or edge embossing

- 2nd Multifiunctional embosser - DESL, DERL, Point to Point – single or double lamination or edge embossing

- All kind of Micro embossing rollers available

- Large selection of rubber rollers available

- Sincro Rewinder

- Leonardo lotioner

Latest technologies available:

- Warm-up Contactless (on demand)

- Micro FLER

Low speed pilot line

Location: Greenbay, USA

Line specifications

- Machine speed: up to 600 m/min, up to 35 log/min

- Paper width: 24.4” (620mm)

- Max roll diameter: 70.86” (1800mm)

- Finish product diam.: 90 - 150 mm (3.54 – 5.91”)

- Multifiunctional embosser:

- Rubber-to-steel, single or double nip

- Single or double laminated DESL/SPOT (Nested)

- Single or double laminated P/P (point-to-point)

- Matched steel, single nip

- Calender (rubber-to-steel)

Latest technologies availble

- Sincro 6.5 rewinder

- Aquabond ply-bonding technology

Low speed pilot line

Location: São Paulo, Brazil

Line specification:

- Machine speed up to 160 m/min

- Paper width up to 500 mm

- Max roll diameter 1,200 mm

- Finish product diam. up to 160 mm

Multifunctional embosser:

- Rubber-to-steel, single or double nip

- Single or double laminated DESL (nested)

- P/P (point-to-point)

- Hybrid Technology

- Matched steel, single nip

- Calender (rubber-to-steel)

- Possibility to set up any type of embossing pattern available

- Configuration and components can be customized based on customer requirements

Low speed pilot line

Location: São Paulo, Brazil

Line specifications

- Machine speed: up to 100 m/min

- Paper width: up to 330 mm

- Max roll diameter: 1,000 mm

- Height Clip: up to 700 mm

- Head: 240, 300, 330 mm

- Format: 1/4

- Double unwinders

High speed pilot line

Location: Lucca, Italy

Line specifications

- Machine speed: up to 700 m/min, up to 45 log/min

- Paper width: up to 600 mm

- Max roll diameter: 1,800mm

- Finish product diam.: up to 200mm

- Multifunctional embosser

- Rubber-to-steel, single or double nip

- Single or double laminated DESL/SPOT (nested)

- Single or double laminated P/P (point-to-point)

- Matched steel, single nip

- Calender (rubber-to-steel)

- Double rubber to steel embosser

- Possibility to set up any type of embossing pattern available

- Configuration and components can be customized based on customer requirements

Latest technologies available

- Constellation 4-roll rewinder

- Active Punzoncini

- Self-Adjusting Machines devices

- Aquabond ply-bonding technology

- Leonardo lotioner

- Warm-up Contactless Next process for embossing

Low speed pilot line

Location: Lucca, Italy

Line specifications

- Machine speed: up to 40 m/min

- Reels: width up to 320 mm - diameter up to 500 mm

- N° 3 unwinders

- N°3 R/S station pre-embosser

- 1st Multifiunctional embosser - DESL, DERL, Point to Point – single or double lamination or edge embossing

- 2nd Multifiunctional embosser - DESL, DERL, Point to Point – single or double lamination or edge embossing

- All kind of Micro embossing rollers available

- Large selection of rubber rollers available

- Sincro Rewinder

- Leonardo lotioner

Latest technologies available:

- Warm-up Contactless (on demand)

- Micro FLER

Low speed pilot line

Location: Greenbay, USA

Line specifications

- Machine speed: up to 600 m/min, up to 35 log/min

- Paper width: 24.4” (620mm)

- Max roll diameter: 70.86” (1800mm)

- Finish product diam.: 90 - 150 mm (3.54 – 5.91”)

- Multifiunctional embosser:

- Rubber-to-steel, single or double nip

- Single or double laminated DESL/SPOT (Nested)

- Single or double laminated P/P (point-to-point)

- Matched steel, single nip

- Calender (rubber-to-steel)

Latest technologies availble

- Sincro 6.5 rewinder

- Aquabond ply-bonding technology

Low speed pilot line

Location: São Paulo, Brazil

Line specification:

- Machine speed up to 160 m/min

- Paper width up to 500 mm

- Max roll diameter 1,200 mm

- Finish product diam. up to 160 mm

Multifunctional embosser:

- Rubber-to-steel, single or double nip

- Single or double laminated DESL (nested)

- P/P (point-to-point)

- Hybrid Technology

- Matched steel, single nip

- Calender (rubber-to-steel)

- Possibility to set up any type of embossing pattern available

- Configuration and components can be customized based on customer requirements

Low speed pilot line

Location: São Paulo, Brazil

Line specifications

- Machine speed: up to 100 m/min

- Paper width: up to 330 mm

- Max roll diameter: 1,000 mm

- Height Clip: up to 700 mm

- Head: 240, 300, 330 mm

- Format: 1/4

- Double unwinders

Analysis available

Our advisory service to unlock data for every aspect of tissue converting. It tracks machine and finished product data and the result is actionable information on every stage of the tissue converting process with a specific focus on the interactions between machinery and paper to identify a path towards enhanced performance of existing products or the development of innovative products. We analyze data of tissue samples and translates it into recommendations on the best machine configuration for the paper product and suggestions to deliver consistent quality and improve OEE.

- Thickness (UNI EN ISO 534, 12625-3, etc.)

- Dry/Wet tensile strength and elongation (UNI EN ISO 12625-4, -5)

- Ball burst resistance (UNI EN ISO 12625-9)

- Absorbency: Basket & Klemm methods

- Grammage & Basic Weight

- Air permeance (UNI ISO 5636-1)

- SA Emtec (Softness, Stiffness, Roughness)

- Roll firmness

- Twin tester (dust measurement)

- Custom analysis on request

- Thickness (UNI EN ISO 534, 12625-3, etc.)

- Dry/Wet tensile strength and elongation (UNI EN ISO 12625-4, -5)

- Ball burst resistance (UNI EN ISO 12625-9)

- Absorbency: Basket & Klemm methods

- Grammage & Basic Weight

- Air permeance (UNI ISO 5636-1)

- Thickness (UNI EN ISO 534, 12625-3, etc.)

- Dry/Wet tensile strength and elongation (UNI EN ISO 12625-4, -5)

- Ball burst resistance (UNI EN ISO 12625-9)

- Absorbency: Basket & Klemm methods

- Grammage & Basic Weight

- Air permeance (UNI ISO 5636-1)

- SA Emtec (Softness, Stiffness, Roughness)

- Roll firmness

- Twin tester (dust measurement)

- Custom analysis on request

- Thickness (UNI EN ISO 534, 12625-3, etc.)

- Dry/Wet tensile strength and elongation (UNI EN ISO 12625-4, -5)

- Ball burst resistance (UNI EN ISO 12625-9)

- Absorbency: Basket & Klemm methods

- Grammage & Basic Weight

- Air permeance (UNI ISO 5636-1)